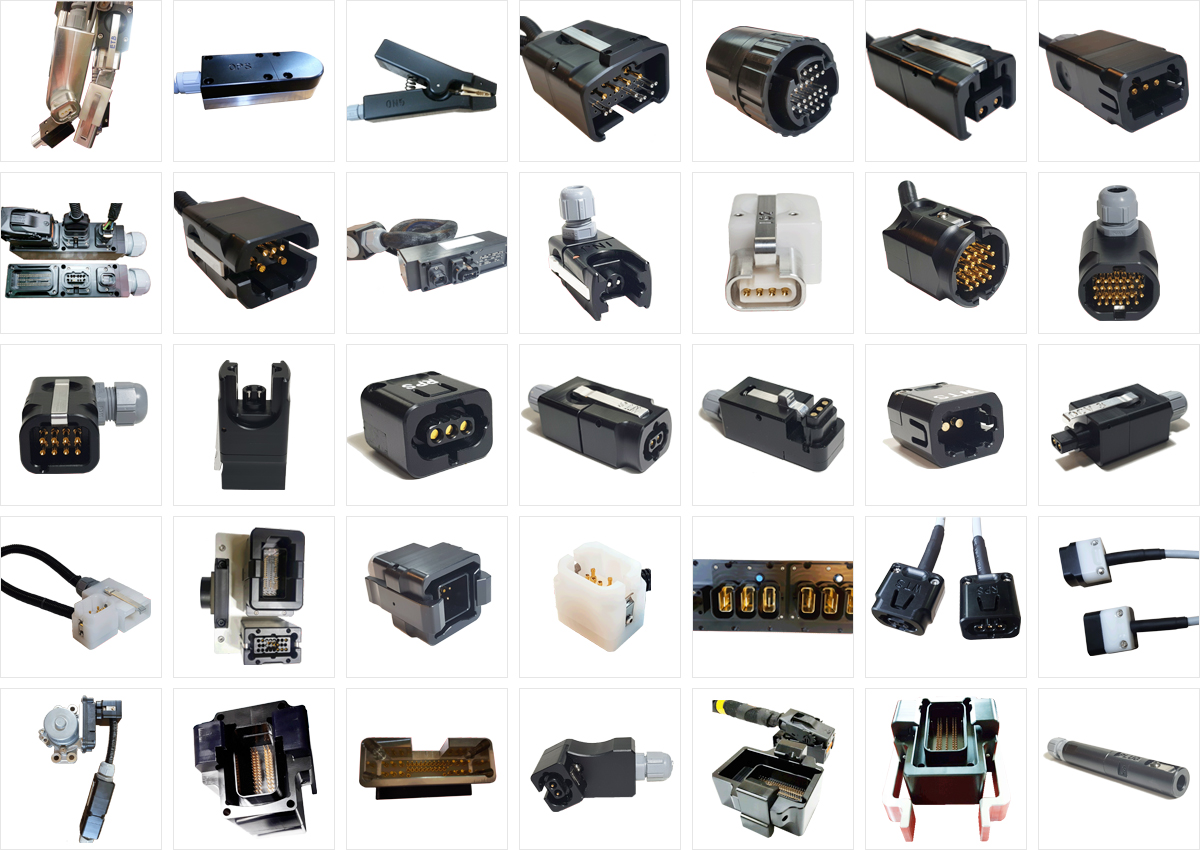

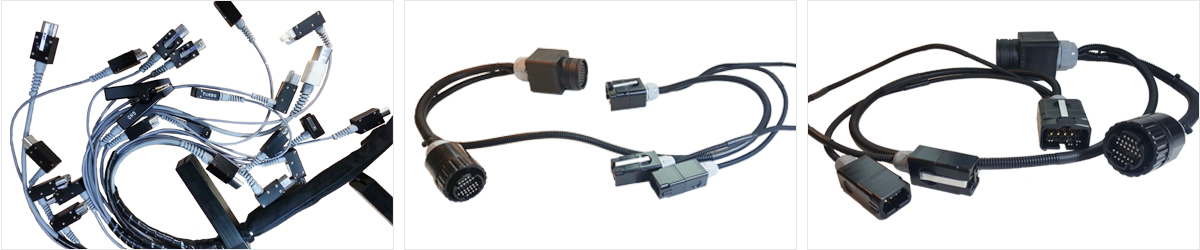

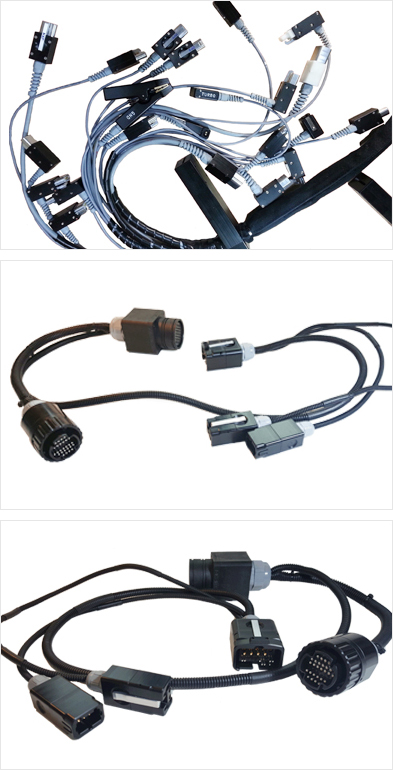

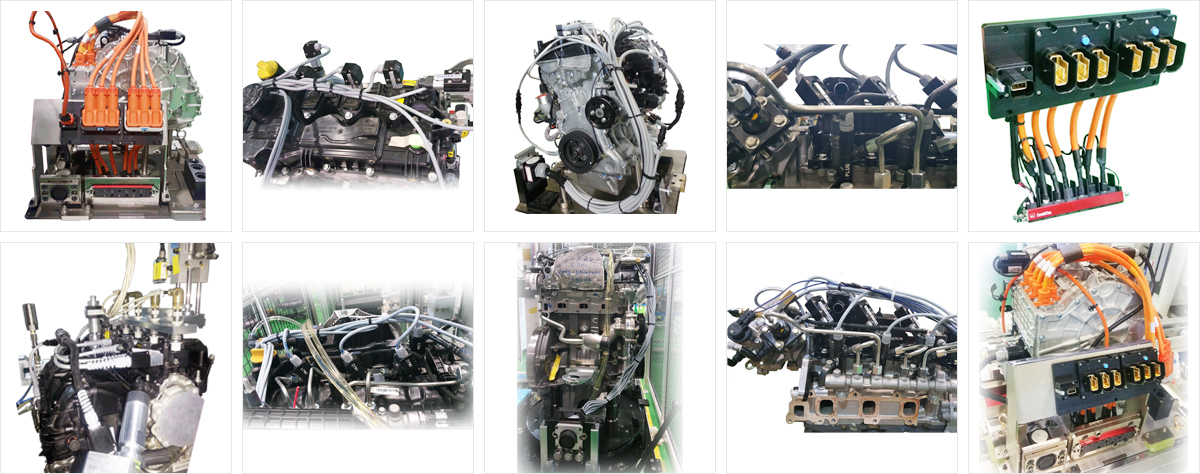

On-Tech has produced test connectors and harnesses based on precise understanding of the function of the vehicle harness’ connectors,

taking into account the environmental conditions such as the flexibility and oil resistance of the cable to be applied

as well as the excellent contact and durability of the test connector.

In addition, On-Tech has designed them ergonomically to allow the operator to easily attach and detach them.

Recently, On-Tech has produced various test connectors considering the proper current and insulation required for high-voltage,

high-current cable for application to Hybrid transmission, and it has got good response from customers.

On-Tech has produced test connectors and harnesses based on precise understanding of the function of the vehicle harness’ connectors, taking into account the environmental conditions such as the flexibility and oil resistance of the cable to be applied as well as the excellent contact and durability of the test connector. In addition, On-Tech has designed them ergonomically to allow the operator to easily attach and detach them. Recently, On-Tech has produced various test connectors considering the proper current and insulation required for high-voltage, high-current cable for application to Hybrid transmission, and it has got good response from customers.